Call us now

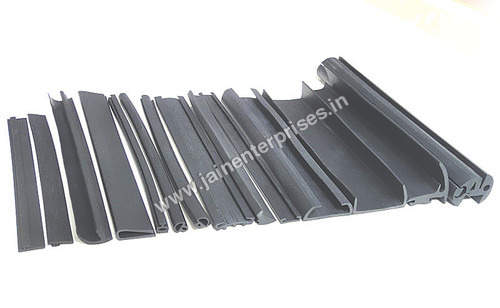

Extruded Rubber Profile

Price 100 INR/ Piece

Extruded Rubber Profile Specification

- Water Absorption

- Low

- Feature

- Weatherproof, UV resistant, Durable, Compression Set Resistant

- Tolerance

- 0.2 mm

- Resistance level

- High resistance to chemicals, oil, weather, and ozone

- Diameter

- Up to 100 mm

- Temperature Resistance

- -40C to +120C (higher for specific compounds)

- Tensile Strength

- 10 MPa

- Thickness

- 3 mm to 30 mm

- Rubber Type

- Solid Rubber, Sponge Rubber

- Style

- Solid and Sponge Profiles

- Usage & Applications

- Sealing, insulation, dustproofing in doors, windows, enclosures, automotive and industrial sectors

- Width

- 8 mm to 100 mm

- Ash %

- 1.5%

- Natural Rubber

- Available on request or as per specification

- Density

- 1.6 Gram per cubic centimeter(g/cm3)

- Length

- Up to 10 meters, customizable

- Components

- Can include double-sided adhesive, steel reinforcement on request

- Color

- Black, available in other colors on request

- Weight

- Variable as per profile and size

- Volatile Matter (%)

- 2.0%

- Nitrogen Content (%)

- 0.5%

- Size

- Customizable as per requirement

- Hardness

- 50 - 80 Shore A

- Flame Resistance Level

- Available in flame retardant grades

- Surface Finish

- Smooth, fine cell structure

- Part Type

- Extrusion Rubber Seal/Strip

- Compression Ratio

- Up to 50%

- Thermal Conductivity

- Low

- Product Type

- Extruded Rubber Profile

- Material

- EPDM, Neoprene, Silicone, Nitrile, Natural Rubber

Extruded Rubber Profile Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- Customized packing

- Main Domestic Market

- All India

About Extruded Rubber Profile

Rubber Profile

Being an undisputed leader in the industry, our company is noted as the reckoned manufacturer and exporter of the Rubber Profile. These profiles are made by our experts using high-end quality rubber that is procured from certified quality vendors. Widely used in electronic appliances, heating equipments and glazing work, these profiles are offered to clients without any delay. Our entire range of Rubber Profile is provided in the best quality packing.

Features:

- Excellent flexibility

- High quality

- Durability

Engineered for Lasting Performance

Our extruded rubber profiles are formulated to withstand harsh weather, chemicals, oil, and ozone exposure. With excellent UV and compression set resistance, they maintain their integrity and reliability for over a decade under normal conditions. Choose from EPDM, Neoprene, Silicone, Nitrile, or Natural Rubber bases, tailored for your specific environmental and mechanical requirements.

Versatile Applications Across Industries

These rubber profiles are ideal for sealing, insulation, and dustproofing needs in automotive, industrial, and construction sectors. Commonly used around doors, windows, enclosures, and machinery, their customizable size, style, and hardness ensure an exact fit for any project. Performance options like flame-retardance, steel reinforcement, or adhesive backing can be specified as needed.

Customizable Solutions for Precise Fit

Every profile is extruded to your specifications with tight tolerances (0.2 mm). Select widths from 8 mm to 100 mm, thicknesses from 3 mm to 30 mm, and lengths up to 10 meters. Available in black or other colors on request, and with options for solid or sponge construction. This flexibility guarantees a snug, effective, and tailored installation for every application.

FAQs of Extruded Rubber Profile:

Q: How are extruded rubber profiles manufactured and customized?

A: These profiles are produced through the extrusion process, where rubber compounds such as EPDM, Neoprene, Silicone, Nitrile, or Natural Rubber are shaped under heat and pressure. Customization is available for size, profile shape, hardness, color, and additional components like adhesives or steel reinforcement, ensuring a precise match for your requirements.Q: What applications are extruded rubber profiles suitable for?

A: They are widely used for sealing, insulating, and dustproofing in doors, windows, enclosures, as well as in the automotive and industrial sectors. Their durability and weatherproof properties make them ideal for environments exposed to UV, chemicals, or temperature fluctuations.Q: When should I choose sponge rubber over solid rubber profiles?

A: Sponge rubber profiles are best for applications needing compressibility, flexibility, and effective sealing against air or dust, such as in door and window gaskets. Solid rubber profiles are preferred where strength, wear resistance, or structural integrity are prioritized.Q: Where should extruded rubber profiles be stored before use?

A: Store these profiles in a cool, dry place, away from direct sunlight to maintain their physical properties and prevent premature aging or degradation. Proper storage extends their shelf life and performance reliability.Q: What are the benefits of using these profiles in exterior applications?

A: Their excellent resistance to weather, UV, ozone, and chemicals ensures longevity and effective sealing, even in harsh outdoor conditions. With a low compression set and water absorption, they retain their shape and efficacy for over 10 years.Q: How do I specify the right profile dimensions and features for my application?

A: Provide requirements for width, thickness, length, style (solid or sponge), hardness, color, and special features like flame resistance, steel reinforcement, or adhesive backing. The manufacturer will assist in tailoring the product to fit your applications technical needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Profile Category

Rubber Beading Cord

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Water Absorption : <2%

Tolerance : 0.1 mm

Resistance level : High (chemical and weather resistance)

Feature : Weather resistant, flexible, durable

EPDM Rubber Profiles

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Water Absorption : 2% (by weight)

Tolerance : 0.5 mm

Resistance level : Excellent resistance to weather, ozone, UV, steam, and chemicals

Feature : Weather Resistant, UV Resistant, Flexible, Durable, Ozone Resistant

Rubber Profiles for Aluminum Doors

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Water Absorption : < 1%

Tolerance : 0.5 mm

Resistance level : High UV & ozone resistance

Feature : Weatherresistant, flexible, soundproof

Glass run rubber flock channel.

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Water Absorption : Negligible, less than 1%

Tolerance : 0.2 mm

Resistance level : High resistance to UV, ozone, and weathering

Feature : Weatherproof, Noise reduction, Durable, Flexible

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS