Call us now

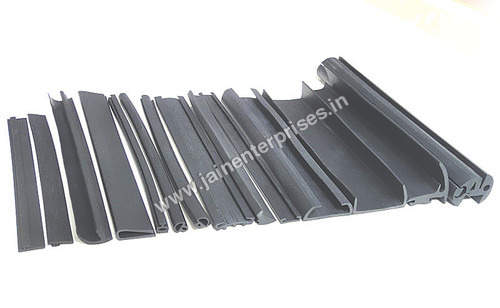

EPDM Rubber Profiles

Price 100 INR/ Piece

EPDM Rubber Profiles Specification

- Surface Finish

- Smooth/Matte

- Nitrogen Content (%)

- 0.5%

- Diameter

- Up to 50 mm (round profiles)

- Thermal Conductivity

- 0.15 W/mK

- Hardness

- 605 Shore A

- Width

- 10 mm to 80 mm (customizable)

- Usage & Applications

- Automotive seals, window and door gaskets, weatherstrips, HVAC systems, construction joints

- Flame Resistance Level

- Meets UL94 HB (on request)

- Tolerance

- 0.5 mm

- Color

- Black (other colors available on request)

- Thickness

- 1.5 mm to 25 mm

- Length

- Up to 50 meters/roll (customizable)

- Feature

- Weather Resistant, UV Resistant, Flexible, Durable, Ozone Resistant

- Ash %

- 5%

- Size

- Custom sizes available

- Material

- EPDM (Ethylene Propylene Diene Monomer)

- Compression Ratio

- 20-40%

- Style

- Solid / Sponge / Custom Profile

- Volatile Matter (%)

- 2%

- Weight

- Variable as per size and length

- Water Absorption

- 2% (by weight)

- Rubber Type

- EPDM

- Natural Rubber

- 0% (100% synthetic EPDM)

- Tensile Strength

- 7~12 MPa

- Density

- 1.25 Gram per cubic centimeter(g/cm3)

- Product Type

- Extruded EPDM Rubber Profile

- Components

- Extruded EPDM rubber, may include steel inserts for reinforcement

- Temperature Resistance

- -40C to +120C

- Part Type

- Sealing profiles

- Resistance level

- Excellent resistance to weather, ozone, UV, steam, and chemicals

EPDM Rubber Profiles Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- Customized packing

- Main Domestic Market

- All India

About EPDM Rubber Profiles

EPDM Rubber Profiles

Owing to our incomparable quality of our products, we are considered as one of the pioneer manufacturers and exporters of EPDM Rubber Profiles. As per industry specific need, these profiles are made by us employing high grade quality rubbers. Available in varied specifications, these profiles are offered to our clients in a safe packing. Widely used for sealing between the glass and aluminum sections, these EPDM Rubber Profiles are offered to clients at feasible prices.

Features:

- Flexibility

- Unmatched quality

- Easy to use

Versatile Sealing Solutions for Demanding Environments

EPDM rubber profiles deliver exceptional weather resistance, UV and ozone stability, making them suitable for both indoor and outdoor use. The products robust chemical resistance and excellent mechanical properties provide secure sealing in automotive, construction, and HVAC applications. Customizable in terms of shape, hardness, and size, these profiles adapt seamlessly to diverse technical requirements.

Advanced Manufacturing and Customization Capabilities

Manufactured through state-of-the-art extrusion technology, each EPDM profile can be tailored for specific dimensions, hardness, and style, including solid, sponge, or entirely custom profiles. Profiles may also be reinforced with steel inserts if needed, ensuring suitability for complex installation scenarios. Color, thickness, width, and length can all be specified by the customer.

FAQs of EPDM Rubber Profiles:

Q: How are EPDM rubber profiles manufactured and customized?

A: EPDM rubber profiles are made using extrusion technology, where heated EPDM compound is forced through a die to achieve the desired shape and size. Customization options include hardness (40~80 Shore A), thickness, width, length, profile style (solid, sponge, round), and color. Dimensions and designs can be tailored precisely to customer requirements.Q: What ensures the durability of EPDM profiles in outdoor applications?

A: These profiles possess excellent resistance to UV, ozone, weather, and steam, with a robust elongation at break of at least 300%. This, combined with superior chemical resistance, allows prolonged outdoor exposure without significant degradation, making them ideal for use in windows, doors, building joints, and automotive seals.Q: In which industries are EPDM rubber profiles typically used?

A: EPDM profiles are widely used in automotive (for door and trunk seals), construction (as window and door gaskets, expansion joints), HVAC (as flexible seals), and other sectors where robust sealing against moisture, dust, or vibration is essential. Their adaptability and range of specifications suit a variety of commercial and industrial settings.Q: What properties make EPDM suitable for electrical insulation and gasket applications?

A: EPDM offers superior electrical insulation due to its low conductivity (0.15 W/mK) and excellent sealing properties. The smooth or matte surface finish and flexibility ensure reliable performance as gaskets and seals, preventing leaks and electrical shorts in sensitive environments.Q: How can customers specify the right EPDM profile for their requirements?

A: Customers can provide specifications regarding size (width: 1080 mm, thickness: 1.525 mm, diameter up to 50 mm), length (up to 50 meters/roll), hardness (customized within 40~80 Shore A), color, and any reinforcement needs. Manufacturers work closely with clients to design and produce profiles that best fit their application and installation conditions.Q: What are the key benefits of using 100% synthetic EPDM versus natural rubber?

A: Unlike natural rubber, 100% EPDM offers enhanced resistance to weather, ozone, UV exposure, most chemicals, and steam. This results in greater longevity, reduced maintenance, and suitability for environments where natural rubber would deteriorate more rapidly.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Profile Category

Rubber Profiles for Aluminum Doors

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Temperature Resistance : 40C to +120C

Components : Single/Multiple chamber extruded profile

Resistance level : High UV & ozone resistance

Part Type : Door & Window Rubber Seal

Extruded Rubber Profile

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Temperature Resistance : 40C to +120C (higher for specific compounds)

Components : Can include doublesided adhesive, steel reinforcement on request

Resistance level : High resistance to chemicals, oil, weather, and ozone

Part Type : Extrusion Rubber Seal/Strip

Glass run rubber flock channel.

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Temperature Resistance : 40C to +120C

Components : Flocklined EPDM profile

Resistance level : High resistance to UV, ozone, and weathering

Part Type : Automotive Rubber Profile

Flocked Glass Run Channel

Price 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Temperature Resistance : 40C to +120C

Components : Main Channel, Flocked Layer

Resistance level : Excellent weather & UV resistance

Part Type : Window Seal Channel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS